Author | Henk Wynjeterp – Regional Lead – Europe | Henk leads Pragma’s OEM after-sales practice for food processing and packaging manufacturers.

Most OEMs (original equipment manufacturers) have embraced some form of after-sales services as a strategic growth priority. Moving from machine sales to advanced lifecycle services promises stronger customer relationships, predictable revenue, and competitive advantage1. But despite this servitization commitment, many OEMs find that effectively scaling services execution across geographies and equipment types is harder than expected.

Technology is seen as an enabler that allows the OEMs to define and deliver new digital services to their clients. These digital services, as well as traditional services, require connected information that supports workflows.

Our experience with OEM clients is that they face information management challenges that inhibit them from providing scalable traditional and digital services. In most cases, these challenges are not isolated. Data fragmentation leads to manual workarounds, which in turn are symptoms of a deeper structural gap: the absence of a digital backbone connecting systems and workflows.

Fragmented data

At the core of most challenges is incomplete or inconsistent data created over many years of operation and across multiple entities. Installed base records are often outdated, spare parts are not reliably linked to assets, and maintenance templates vary by region or even by technician. Without a trusted single source of truth, service teams struggle to plan effectively, accuracy suffers, and quoting cycles slow down. Success depends on data stewardship, and master data quality is a primary success factor in any EAM (enterprise asset management) system. Indeed, our engagement with a leading OEM started 20 years ago on a foundational commitment to sort out master data first, and today they are still harvesting the fruits of that commitment.

Manual execution

As a symptom of fragmented data, even after service contracts are signed, execution often depends on manual processes. Maintenance must be aligned with actual customer and machine parameters; field feedback happens in MS Office software or homegrown applications (often late and incomplete); invoicing for services requires spreadsheets and workarounds; and critical information is trapped in disconnected systems, requiring manual searches. The result is administrative overhead, and employees spend their time chasing data updates, validating maintenance feedback or correcting errors. This not only limits execution capacity but also makes it nearly impossible to deliver consistent, predictable service at scale.

The missing EAM system backbone

OEMs have a good grasp of PLM (product lifecycle management), ERP (enterprise resource planning) and CRM (customer relationship management) systems. These systems primarily support manufacturing processes and are used by different specialist groups. Research and Development teams use PLM, engineering or production teams use ERP, and sales teams use CRM. For Services, OEMs aim to use FSM (field service management) software alongside ERP or CRM systems.

The problem is that setting up an ERP for discrete manufacturing is very different to configuring for services. Quite often, there are multiple ERP systems due to different manufacturing sites from previous acquisitions. Furthermore, none of the systems are designed for risk-based maintenance task definition and management, which is the basis for service contract definition and execution. The result is that systems are stretched ineffectively to provide functionality they do not naturally have, creating a void between the asset register and work execution.

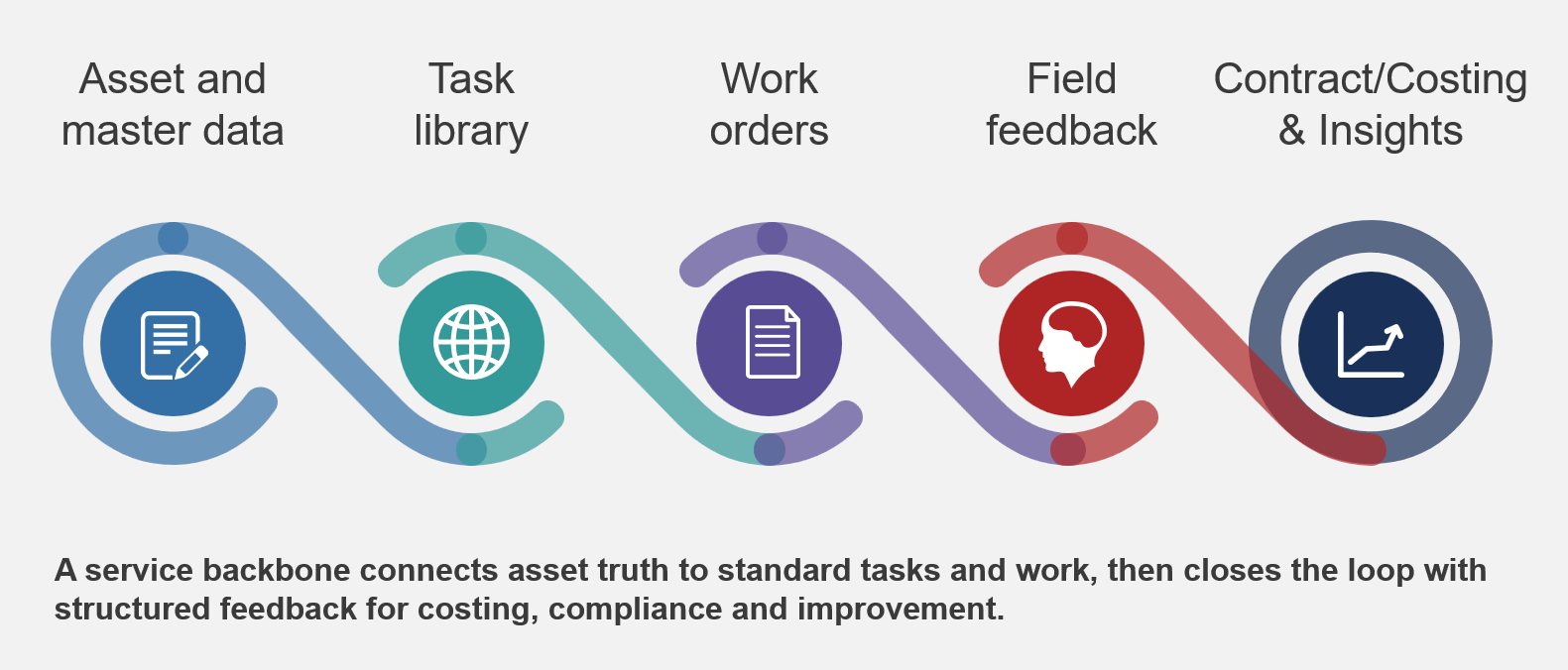

| Building the digital platform Scaling services requires a reliable digital backbone that connects information, systems and execution. Accurate asset data, standardised maintenance templates, and connected workflows are essential to turn services strategy into execution. An enterprise asset management system provides this digital platform. It is designed to link asset registers with maintenance tasks and work orders, while seamlessly connecting with ERP, CRM, and FSM systems. |  |

With the right EAM system in place:

- data becomes accessible through a single source of truth,

- service contract estimation and maintenance execution are automated,

- growth becomes scalable and sustainable.

When information flows into execution, consistency stops relying on heroics and starts to scale. At Pragma, our On Key team has developed EAM software capabilities designed for OEMs to strengthen installed base management, service plan creation and performance management. If scaling your services is a priority, On Key should form part of your digital services platform.

See the On Key Product Suite here.

Reference