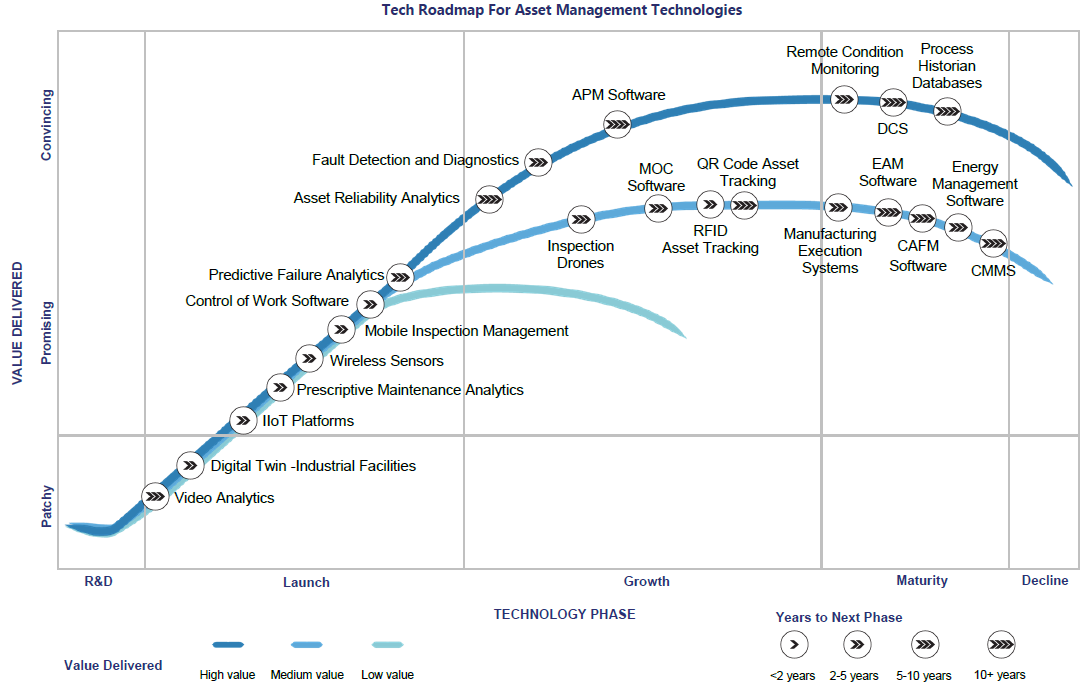

Back in 2019, researchers from Verdantix identified the trends in technology roadmaps for asset management technologies and compiled a helpful graphic to illustrate the value and associated growth of these technologies. Of interest to us at the time was the rapid growth and high value associated with Asset Reliability Analytics, Fault Detection and Diagnostics and Asset Performance Management software. Even more exciting was the high value related to Remote Condition Monitoring technologies that started reaching maturity.

Timely technologies for a global pandemic

Fast forward to July 2021, and we realise just how timely these technologies were to help mitigate health risks and save critical assets and companies alike. The continued disruption of business operations caused by the Covid-19 pandemic has globally expedited the need for digitalised and remotely managed business processes and assets, especially in the maintenance management arena.

The realities of in-person transmission of the virus and health protocols to keep people away from each other and from high touch points begs for the implementation of alternative solutions to monitor the reliability, performance and health of assets, especially those critical to the continued operation of businesses.

Technologies and your asset care plans

With constrained resource movement and availability, time is of the essence.

Monitoring and predicting the potential failure of an asset remotely, builds in a buffer to action cost-effective, controlled and timely preventive actions and avoid breakdowns of assets, such as standby generators, not performing when suddenly required to do so.

Your digitalisation strategy and technology roadmap ties in with your asset management strategy and asset care plans. You require a clear understanding of the criticality of each asset and its associated function, its failure modes and the effect on your operation. This information will help you determine the best maintenance tactics of which the rise of predictive maintenance are emphasised in the Verdantix report. Technologies enabling predictive failure detection are of high value and are a driving force changing the maintenance and reliability landscape. Not only do these technologies offer you the capability of 24/7 real-time online access to monitor the health of your equipment and to receive timely warnings before potential failures. These systems should also triggers the selected corrective maintenance tasks and get your maintenance teams working on the problem before you even know of it.

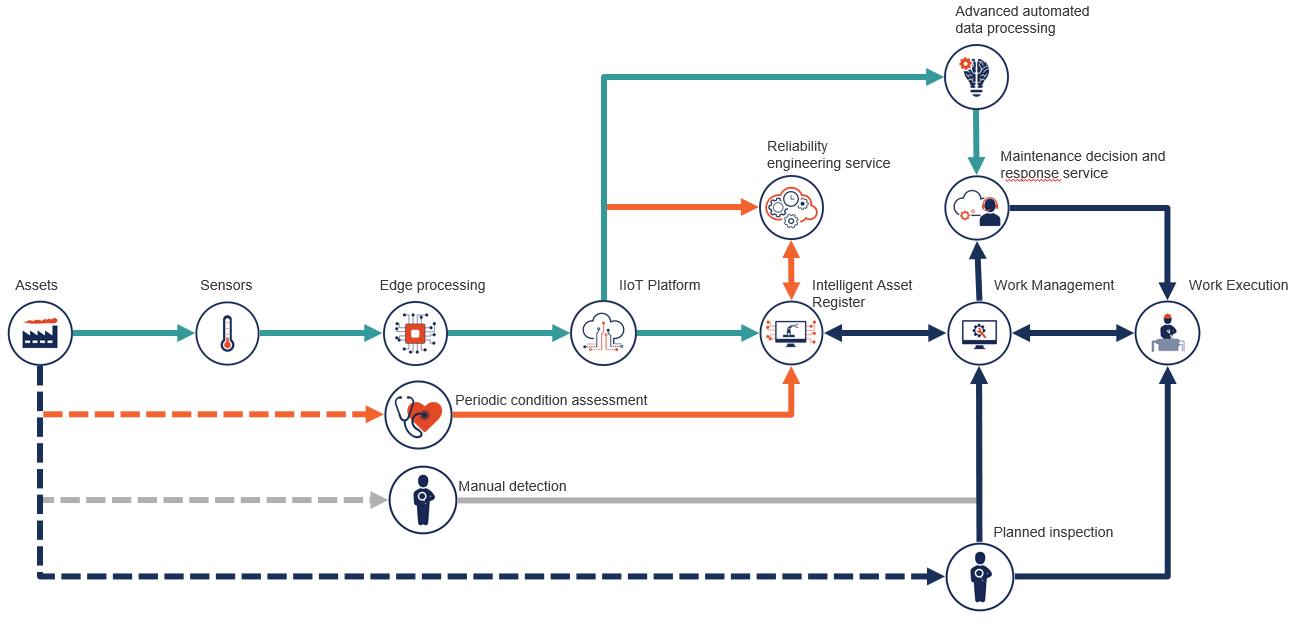

Visualising your asset management processes can also help determine how to deploy technologies in your operation. Below is a simple diagram depicting various scenarios from a planned inspection to a manual detection, periodic condition assessment, an IIoT enabled condition monitoring value chain, along with how each one feeds into the work or maintenance management process.

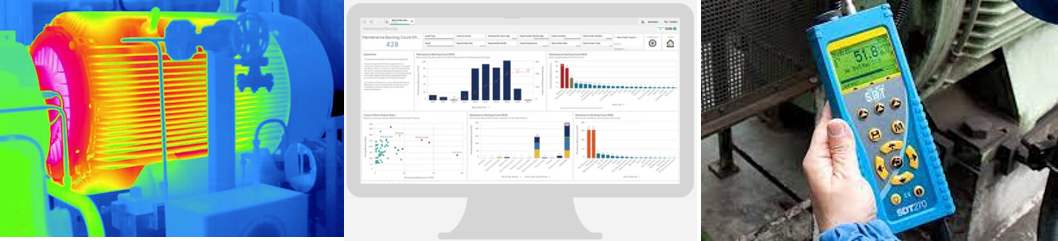

A holistic approach to condition monitoring technologies and sensors

The growing scope and availability of predictive condition monitoring technologies and sensors has given many companies a way to convert their assets to “smart assets” and adapt their maintenance processes and tasks with the enriched information derived from data provided by these smart assets.

We found that the success of the use of technologies hinges on a holistic approach.

Individual technologies as such aren’t the silver bullet, but correctly scoping the stack of correct measurement and assessment technologies that provide the required information should be used in combination with the required expertise to analyse the data and tweak the frequency of asset monitoring.

Randomly selecting technologies proves to be costly. It would be best to consider the technologies you already have and the interfaces or integrations required to develop the most practical and sustainable system landscape for your needs. If you are concerned about the needed investment, a technology roadmap can help with a cost-effective approach that can be expanded. The importance of a use case should also not be underestimated as it can help validate the return on your investment before you commit to the costs.

An example of a technology roadmap can be found here. It depicts a systematic approach to a holistic solution for organisations, both big and small.

The value of in-time asset health monitoring and analysis

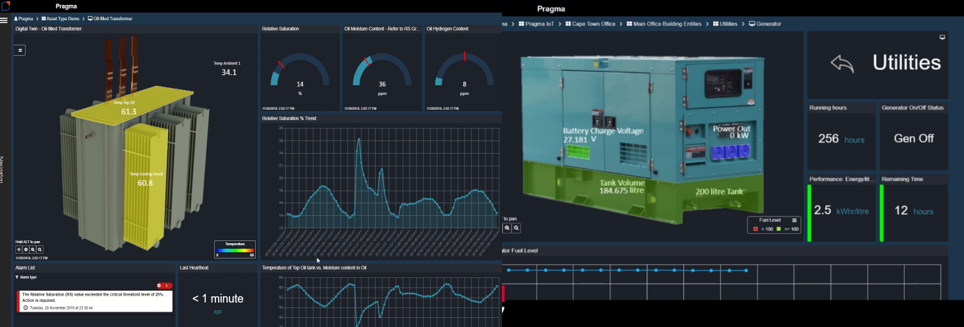

In-time monitoring and analysis provide reliability and maintenance engineers access to visualised real-time data dashboards, which provide them with information about an asset’s health status and its associated risk levels. These solutions typically use engineered algorithms for predictive analytics, which gives reliability engineers a better sense of the overall status of asset or equipment reliability, but it also enables them to make better decisions to increase this reliability and overall integrity of a plant asset-dependent organisation.

In-time monitoring and analysis also enable local and remote monitoring and support to allow for the most efficient decision-making when coupled with in-depth analysis and expert advice on corrective actions to maintain uptime and increase asset or equipment longevity.

The digital twin

A step up from basic condition monitoring is asset digitisation, which allows for the development of digital twins with the visualisation of the asset’s condition and its associated process parameters in real-time. Alarms and notifications can be triggered to warn of any asset anomalies and ultimately prevent asset downtime. Where this is coupled with an automated work management process where work orders are created based on the anomalies identified, you have predictive maintenance without any human intervention.

Imagine the transparency this will achieve for the state of your critical assets. You will be able to track utilities, like water and energy usage or the fuel levels of your standby generator, which is a highly critical asset in the South African context, given load shedding. You will understand exactly what is happening inside your oil-filled transformer, and you will be able to make decisions that will help you significantly reduce costs, the risk of failure, downtime and even the impact on the environment. Digital twins help to ensure a more reliable and optimal performing asset-intensive organisation or any small business for that matter. The power of having access to live information and a built-up history of asset information or failure trends enables predictive responses to reliability-centred maintenance. It provides peace of mind to asset and business owners.

Agility – the core of the smart organisation

But perhaps the most important tool one can have is agility, to be able to respond quickly and efficiently to manage our assets better. Predictive maintenance enables this, avoiding or reducing downtime and ultimately ensuring that expensive repairs and maintenance work are either avoided or planned accordingly. Maintenance readiness is also vital, taking into consideration a whole lifecycle asset management approach. Agility is also our ability to think and understand quickly. We must process all the information we are bombarded with as quickly as possible, and importantly, extract what will add value to our respective organisations or businesses.

In closing, just as it is important to monitor one’s heart rate regularly and respond to anomalies, asset health monitoring is literally having your finger on the pulse, enabling informed and predictive decision-making. It is vital that organisations or businesses in South Africa start developing a digitisation roadmap and gradually commence on a journey to sound and sustainable asset management reliant on intelligent assets and smart asset owners.