About this course

In this course you will gain the necessary work planning and scheduling knowledge and skills to:

- Increase the amount of maintenance work being accomplished without any additional resources.

- Free up labour resources and reallocate them to value-adding activities.

- Introduce continuous improvement activities to your current maintenance planning processes.

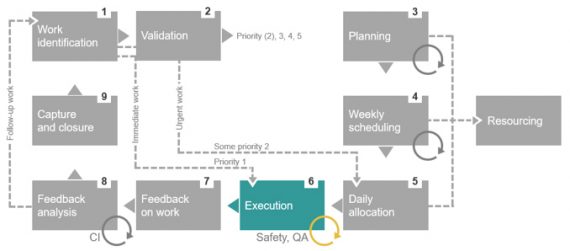

You will get to grips with the requirements of each of the steps in the Maintenance Work Management cycle, associated responsibilities and best practices. The efficient processing of tactical and non-tactical work through the cycle will ensure that you drive asset reliability improvements while efficiently using available resources.

Sound Planning and Scheduling principles, when applied at your plant will ensure that you have a standardized, repeatable process.

Outcomes

Evaluate and compare different Maintenance Work Management cycles

Explain how software applications and document controls can meet the requirements of Maintenance Work Management

Identify and prioritise work arising through notifications or work requests

Describe the benefits and explain the different roles and responsibilities when following a controlled Maintenance Work Management process

Scope and plan the work arising based on the notification or work requests

Apply effective planning techniques for tactical and non-tactical maintenance

Monitor execution activities and review work order feedback for optimisation purposes

Interpret production plans, resource requirements and opportunities for tactical maintenance

Discuss and implement solutions for recurring repair and maintenance problems and the optimisation of basic maintenance strategies

Analyse and interpret Maintenance Work Management reports for management and control purposes

Introduction

This module provides you with an introduction to the maintenance management model that supports a healthy maintenance work management process. The module provides the benefits and details the justification for the investment in a robust maintenance work management process.

Process Overview

This module builds on the maintenance management model from the introduction and provides the context within the asset life cycle. You will be introduced to the documentation and various information and software systems that are integrated with maintenance work management.

Validation and Approval Process

This is the first module that starts to unpack the Maintenance Work Management cycle; it emphasises the need for quality data from the source and demonstrates how effective validation drives an efficient process to the end.

Planning and Scheduling Principles

This modules unpacks the 12 principles of planning and scheduling that underpin all the decisions and activities that planners and schedulers should be making.

Execution and Feedback Process

This module emphasises the transfer of responsibility from the planning department to the first line supervisors responsible for how the work will be executed. It also looks at how the process loop is closed, ensuring a robust continuous improvement cycle for maintenance work management.

Planning Activities

In this module we apply the six planning principles and dig deep into the planner’s responsibilities and activities necessary to structure a comprehensive work package for execution.

Scheduling Activities

In this module we apply the six scheduling principles and provide the scheduler with the tools to utilise the information in the EAM system to be able to rank the work from the backlog, ensuring that the most important work is executed in an environment where resources are limited.

Resourcing

The interaction between resourcing, planning, scheduling and work execution requires mutual understanding and coordinated prioritisation, this module looks at the different aspects of this.

Long Term Work Plan

The long term workplan and the alignment of the operating environment constraints with the maintenance and reliability expectations is critical. This module explores how the long term workplan can be used to optimise the use of maintenance and external resources.

Tactics Optimisation

Having explored optimisation opportunities arising from the Long Term Work plan you are introduced to some fundamental principles of maintenance tactic development and this modules will open your eyes to a broader set of opportunities for further optimisation.

KPIs, Reporting and Analysis

Then last, but by no means least, we wrap-up the course by exposing you to typical work management KPIs are used in industry and how these can be used to optimse planning, scheduling and work management.

Who should attend?

- Maintenance supervisors

- Maintenance planners

- Maintenance schedulers

- Maintenance coordinators

- Maintenance foremen

Format and duration

- 3 day face to face classroom

- 6 x 4 hours Virtual classroom

- Blended learning with 8 hours virtual classroom activity and 16 hours of self-directed elearning

Certification

- ECSA endorsed for 3 CPD points