About this course

Train your Maintenance Supervisors and their peers to do effective root cause analysis in support of your focused improvement drive.

This practical course covers Level 2 problem solving, where a small multi-disciplinary team must solve a medium-sized technical problem within one to two weeks.

The focus of the course is on root cause analysis using a causal tree for a real-life scenario.

Course Outcomes

Explain the importance of effective problem solving to achieve the company’s objectives

Explain the principles, rules and traps for root cause analysis

Describe the three levels of problem solving and the role of the supervisors in it

Apply these rules to develop a logical causal tree for a given problem

Explain the steps in the IDMAIC problem solving process

Use evidence to identify and confirm the root cause(s) of the problem

Clearly define a given problem based on the available information

Identify and prioritise possible solutions to prevent a recurrence of the problem

Describe the importance of accurate data for effective problem solving and how it can be obtained

The need for structured problem solving

Explain the importance of effective problem solving to achieve the company’s objectives.

A framework for effective problem solving

Describe the three levels of problem solving and the role of the supervisors in it.

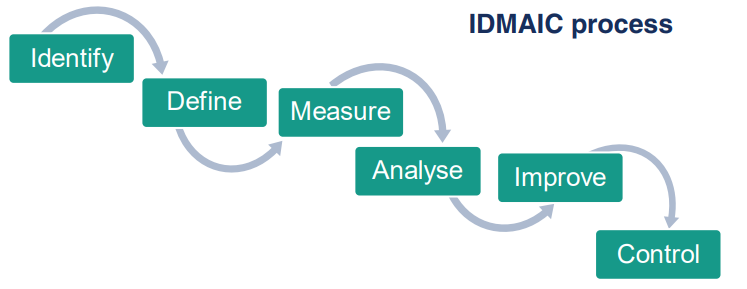

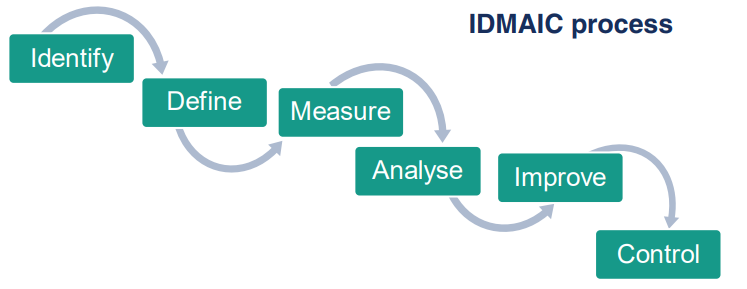

Overview of the IDMAIC process

Explain the steps in the IDMAIC problem solving process

Define: Understand the problem

Clearly define a given problem based on the available information.

Measure: Collecting accurate information

Describe the importance of accurate data for effective problem solving and how it can be obtained.

Analyse: Causal trees and verification using evidence

Explain the principles, rules and traps for root cause analysis.

Apply these rules to develop a logical causal tree for a given problem.

Improve: Identifying possible solutions

Use evidence to identify and confirm the root cause(s) of the problem.

Identify and prioritise possible solutions to prevent a recurrence of the problem.

L2 Problem Solving in Practice

Explain how Level 2 problem solving works in practice in terms of duration, responsibilities and deliverables.

Who should attend?

- Maintenance Supervisors

- Production Supervisors

- Maintenance Planners

- Senior Technicians

- Engineers-in-training

Format and duration

- This course can either be delivered as VILT (Virtual Instructor Led Training) or face to face ILT (Instructor Led Training)

- 16 notional hours

Take-home tools

- Participants will get a copy of a Level 2 Problem Solving template which they can take home and customise for future use.

Certification

- ECSA endorsed for 3 CPD points

Please Note: Individual laptops are a requirement for this training for the following reasons:

- The root cause analysis will be done using an online brainstorming tool (Mural)

- The practical exercise requires the completion of a MS Word template

- A final knowledge quiz must be completed on the Pragma LMS