Author | Stefan Terblanche, Pragma Partner Consultant

Over the last decade, more and more Original Equipment Manufacturers (OEMs) have targeted after-sales services as a value-adding offering to complement their traditional focus on capital sales. Margins on capital equipment have been under pressure, and support from OEMs has become an important selection criterion in evaluating and acquiring new equipment. Selling services is now essential if OEMs are to sustain their capital sales and grow their overall sales revenue. However, for many OEMs that have operated in an equipment-centric environment, this shift to becoming a more service-focused organisation presents many challenges.

What are these challenges, and are there any guidelines or solutions enabling OEMs to serve their clients better and ultimately influence revenue growth in a highly competitive market?

Let’s start by having a look at some of the industry challenges facing OEMs:

- Accurate installed-base information: Do you know which items of equipment you have in your installed base, where they are, their condition and their operating behaviour? OEMs must maintain an accurate record of their installed base, which can be an onerous task, especially when dealing with diverse equipment types and varying locations.

- Equipment performance: Do you know how all your equipment items perform and what their ideal performance should or could be? Ensuring that equipment operates at peak performance is a constant challenge. To keep clients satisfied, OEMs must closely monitor asset performance.

- Equipment-related costs: Is the cost of operating and maintaining your equipment optimal or competitive in your industry? Managing equipment-related costs, including maintenance and replacement parts, is vital to maintaining profitability.

- Demand planning: Do you know the after-sales potential of your installed base? Are you making good decisions when investing in new capabilities? Accurate demand planning is critical, as OEMs need to have the right resources and parts available at the right time to fulfil maintenance requirements.

- Optimal maintenance: Are you performing the right maintenance on your equipment based on operating conditions and your clients’ maintenance budgets? Striking a balance between preventive, predictive, and reactive maintenance can be complex. Overmaintenance is costly, while undermaintenance can result in equipment failure and client dissatisfaction.

Besides the industry challenges, internal organisational challenges are often an even larger issue. These typically include:

- Investment in serviced growth: To grow, investment is required, but how do you balance long-term investment objectives with short-term gains? Having a clear vision and strategy is essential in moving from an equipment to a service-focused organisation.

- Increased productivity: How do you maintain high levels of productivity and smarter ways of working whilst growing? Improving service effectiveness and productivity of your resources is essential. Not being able to meet your clients’ expectations will impact your revenue.

- Installed-base intelligence: How do you harness installed-base intelligence and understand what is included in the installed base? How is it being used, and what service products can be offered? Utilising data from the installed base to make informed decisions and identify trends is a growing challenge as data volumes increase.

- Avoiding cross-subsidies: How do you prevent services from being offered free of charge to subsidise equipment sales and instead get clients to pay for services delivered? Ensuring that service costs are distributed fairly among the various OEM departments prevents cross-subsidies that can erode overall profitability.

- Service culture: How do you create a culture with clear ambitions and practical goals? Establishing a service culture that prioritises client satisfaction, support, and ongoing service improvements is essential.

It is evident that there are many external and internal ‘moving parts’ for an OEM to consider as part of delivering world-class after-sales services. To compound issues even more, these ‘parts’ that must move and function together often belong to different departments at the OEM – capital sales, the help desk, the parts department, field services, or the engineering department. Creating a shared after-sales vision in the organisation is essential to meeting many of the challenges listed in this article.

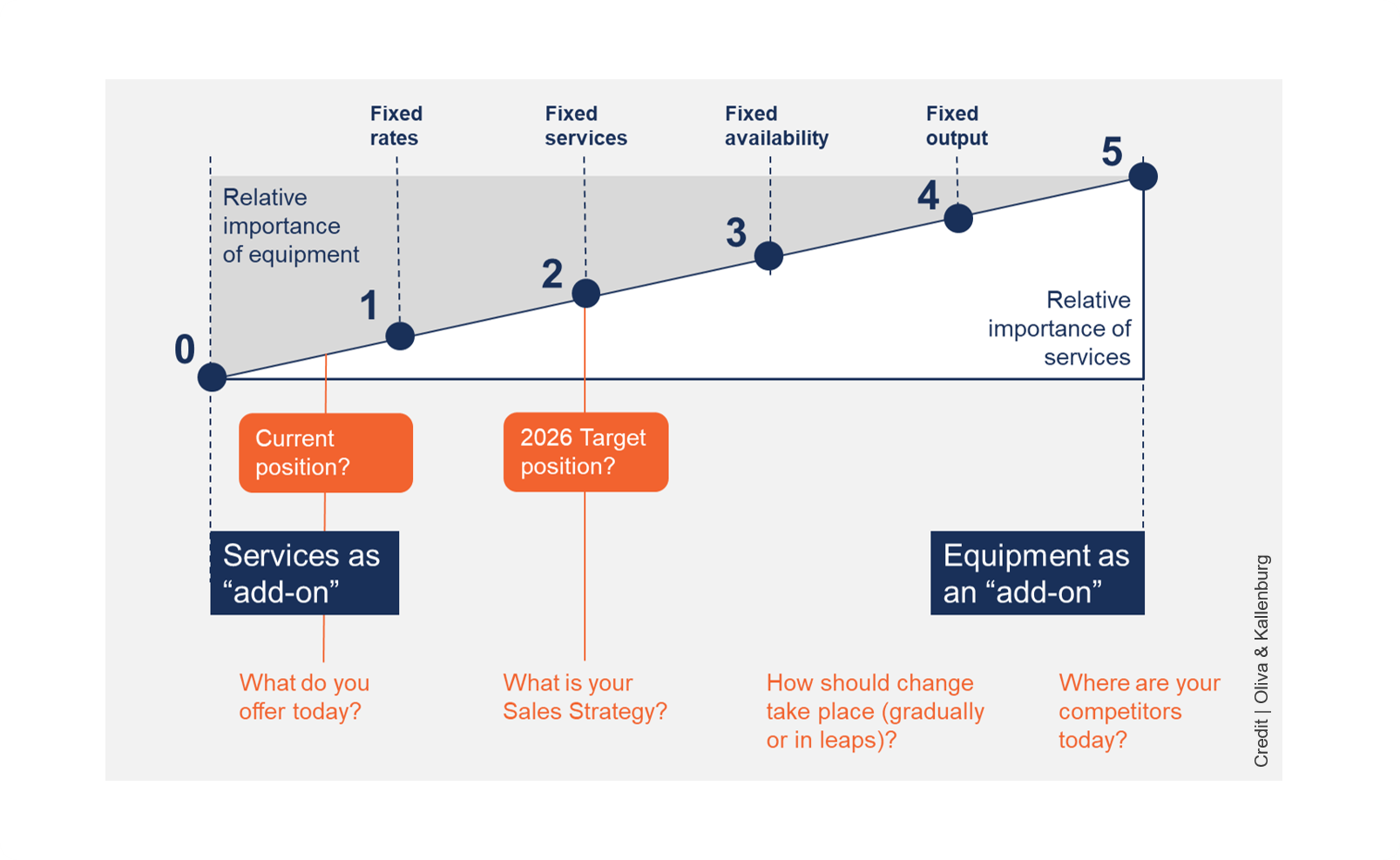

The starting point in most cases is having a clear after-sales goal related to servitisation. The model below depicts the equipment-service continuum, a progression from being an equipment-centric to a service-focused organisation. Where do you want to position yourself on this continuum in the next couple of years? Where are your competitors, and how will you differentiate yourself from them? What is the market expecting? Are you only providing equipment services at a standard rate (position 2), or guaranteeing the output from equipment (position 4)?

To close this gap, you also need to understand your current position. Conducting a ‘zero measurement’ or an ‘after-sales assessment’ is a valuable exercise highlighting the current state of all the ‘moving parts’ of the after-sales engine. It is a great change management exercise, and once the current state is clearly understood and there is alignment towards a common vision or goal, an after-sales strategy can be developed to drive service improvement for the coming years.

Explore Pragma’s solutions to help original equipment manufacturers servitise their offerings here.