The case for having a reliability centred maintenance approach has been proven time and time again. Yet, it is one of the most significant physical asset management challenges facing large, diversified organisations today. By sticking to best practices and getting the foundations of asset management in place, RCL Foods has managed to overcome this challenge.

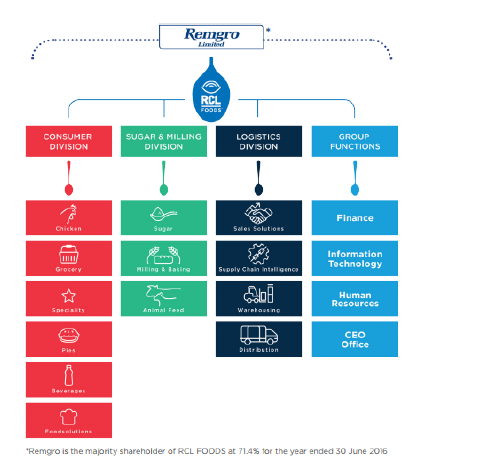

RCL Foods manufactures and distributes a wide range of branded and private food labels in various Southern African countries. In line with their strategy, they have transformed from four separate companies (TSB Sugar, Rainbow Chicken, Foodcorp and Vector Logistics) into a single, integrated business. RCL Foods’ food and logistics divisions are supported by a group services division who is responsible for delivering services like asset management throughout the organisation.

The group did not have control over their asset-related data and no uniform reporting structure. An internal study revealed numerous hurdles in establishing credible asset management practices that would aid the services team in getting more value from the company’s investment in physical assets. They found that the group did not use a standard enterprise asset management (EAM) system or standardised EAM processes.

While some teams used On Key, an EAM system developed by Pragma, different versions of the system were implemented on separate databases. Without a standard asset management blueprint to abide by within the group; policies and procedures, best practices and asset management standards were non–existent or unaligned. RCL identified Pragma as their preferred asset management partner. Pragma was commissioned to introduce On Key as RCL Foods’ centralised EAM system and had to add new business groups to the existing sites.

To enable uniform standards, business processes and reporting across all the business groups, a single database with multisite configuration were implemented. Pragma also developed standard KPI-based analytics reports that are hosted in On Key. These efforts allow RCL Foods’ group services team to gain a holistic view of physical asset performance information across multiple sites. Today, RCL Foods’ asset management blueprint, dubbed the Standard Asset Management Way, consists of all the relevant policies, procedures and best practices within the group.

To enable uniform standards, business processes and reporting across all the business groups, a single database with multisite configuration were implemented. Pragma also developed standard KPI-based analytics reports that are hosted in On Key. These efforts allow RCL Foods’ group services team to gain a holistic view of physical asset performance information across multiple sites. Today, RCL Foods’ asset management blueprint, dubbed the Standard Asset Management Way, consists of all the relevant policies, procedures and best practices within the group.

The organisation has already started reaping the benefits. The senior management team now has a view of the asset management performance of all different operations across the organisation. In addition, optimised maintenance procedures resulted in:

- performance of assets improving,

- minimised risks, and

- a reduction in maintenance costs.

Furthermore, the group has also seen a growth in their asset management maturity moving away from fire fighting into a more preventative, stabilising phase.

Next steps

RCL has implemented the foundations of their Asset Management road map, where they can start stabilising, improving and optimising their asset management journey. To aid their journey Pragma’s Asset Management Improving Assessments (AMIPs) will help them identify the next steps. Other AM initiatives will include the identification of training needs and learning pathway development for critical asset management roles.

The team is also in the process of formalising their Focus Improvement (FI) processes, applying formal spare parts administrations practices and optimising their asset care plans.

Our partnership approach enables us to help our clients mature their asset management over time. The physical asset management journey is never complete. Advances in technology will offer newer and better solutions in the future; this is when we’ll be there to advise the client on the best way forward.