Organisations often struggle to effectively identify and address recurring problems that cause waste, poor performance and ultimately low staff morale. Furthermore, attempts to rectify these problems can be disjointed because of a lack of structured meetings and people taking ownership.

Stock standard reports also fail to provide users with the opportunity to delve into the data for detailed analytical purposes. Pragma’s Focused Improvement (FI) service and toolset are ideal for implementing a system and practices for structured and focused improvement activities, thereby addressing asset-related problems and performance gaps within the organisation.

Focused Improvement concentrates improvement efforts on the areas with the greatest leverage to achieve real breakthrough improvements. A daily review meeting takes place and people are provided with the skills to do effective problem solving. This combination ensures successful and sustained performance improvement.

Why consider a focused improvement approach on your plant?

- The results stemming from focused improvement are quick, tangible and visible.

- Projects are aimed at improving the optimal performance of assets, achieving constant reliability.

- Asset owners gain control and management of maintenance and operational costs.

- A formal methodology instead of guestimates is used to identify projects that will render the most leverage.

- Quick wins help overcome initial internal resistance to change and build momentum for the improvement process and larger projects.

- Problem solving becomes intrinsic to the organisation resulting in a culture of continuous and sustainable improvement.

- Your staff are trained and enabled to effectively drive focused improvement.

- Communication channels between different departments involved with asset care are established and cooperation is greatly improved.

- Regular contact with focused discussions improves problem-solving and allows for constructive feedback and further recommendations.

- Employees know what is expected of them and their actions are aligned with the common goal of the project at hand.

- Discipline and accountability are instilled within the team and on-site.

- Information becomes available for effective decision making.

- The analysis tool has an intuitive user interface allowing for staff to quickly master and effectively use it.

- The tool offers dynamic and flexible in-depth data mining.

- The visual properties of the reports that allow for specific preferences will have users identifying problems within minutes of using them for the first time.

- Mobility is key and the reports can be viewed on tablets which can easily be taken into meetings where new queries can instantly be viewed.

Pragma’s approach to focused improvement

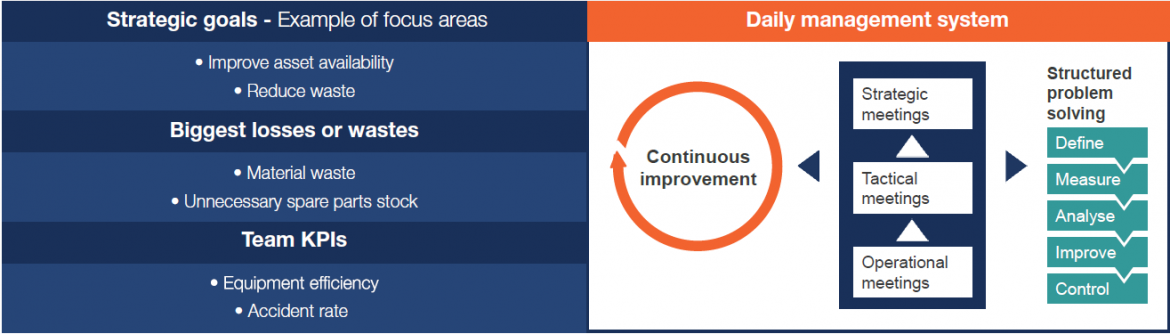

At the heart of focused improvement is our ambition to ensure that our clients achieve their asset management goals. Sometimes a very focused intervention is required to identify the root of a recurring problem and successfully address it. The combination of our people expertise and our tried and tested process has literally saved our clients millions of dollars over the years. Here is our approach:

- We use proven methodologies to define focus areas.

- FI standards and procedures, including the design of the daily review meeting and coordination of the failure analysis requirements, are developed in cooperation with the client.

- In a daily meeting the previous 24 hours’ performance is reviewed, priority actions for the next day are planned, and problem solving or escalations are triggered.

- A structured problem-solving methodology based on the DMAIC steps as used in Six Sigma is established.

- Key resources are trained and enabled in structured problem solving.

- Improvement opportunities are analysed, quantified and prioritised to identify FI projects.

- Asset management KPI threshold limits are set to trigger FI projects.

- Master data that is required for failure analysis is collected and configured. Analysis codes are configured in the Enterprise Asset Management system to identify recurring problems when analysing work order statistics.

Our analytics tool: On Key Insights

The analysis tool displays asset type failures, failure types, failure counts, repair types and root causes, and the associated work orders help the user to quickly spot anomalies and/or potential focus areas. All information is linked, which provides almost unlimited drill-through capability for analysis purposes. Work performed can accurately be compared in terms of cost, time and count indicating, for example:

- which asset had the most failures, how long it took and how much it cost, or

- which assets had the most failures vs which assets required the most labour vs which assets cost the most in terms of breakdowns.

More features of On Key Insights include interactive visualisation (like maps). These can be included so that different perspectives can be considered during analysis and data can be collated and shared with other users.

This system agnostic tool can be accessed by most web-based platforms, and it can seamlessly integrate with most reputable EAMS or CMMS solutions on the market.

Speak to us if you have a recurring problem on an asset, on a production line or on a section of your plant. We have the expertise, processes and tools to solve it for you.