Maintenance work management is the core of maintenance management. It is where all the plans and strategies become reality; it is where Maintenance and Operations meet face to face.

It is where the effectiveness of the material management function and the information management systems are tested; it is where the competence of supervisors, planners and craftsmen are demonstrated, and where the success and cost-effectiveness of a maintenance management system are determined. This is where it all comes together – where the rubber hits the road!

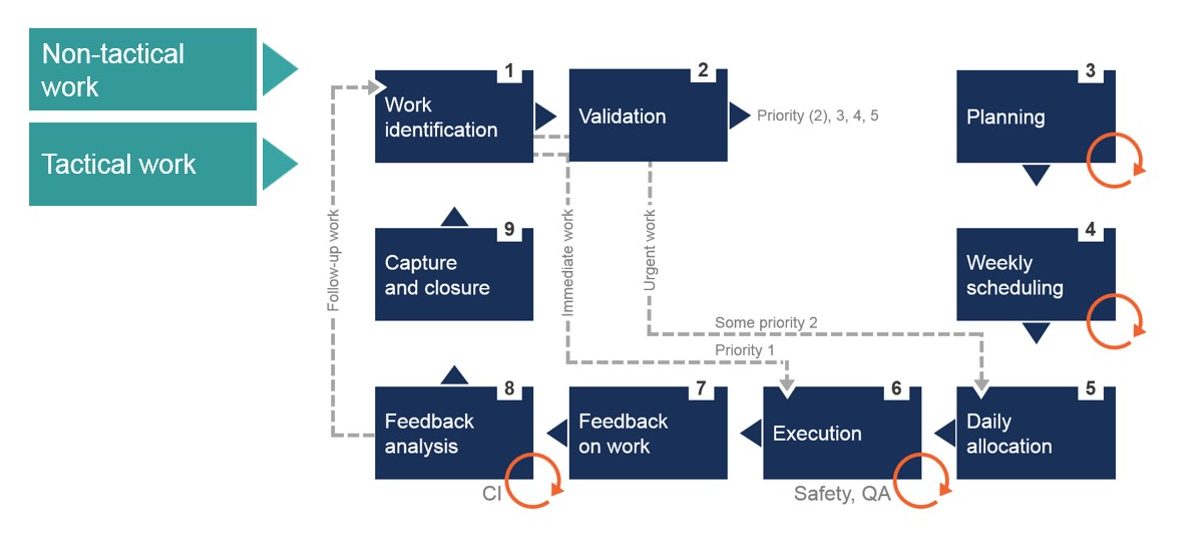

An effective work planning and control (WPC) processor system identifies and validates all the maintenance work to be done (both tactical and non-tactical), match it with the required resources through proper planning, schedules when it will be done, allocates the tasks to competent individuals and ensures that it is done correctly and timeously. Finally, the work details and costs are captured for reporting and analysis purposes.

When should you seek help with work planning and control?

The lack of a proper WPC process and system can cause several systemic issues such as:

- No record-keeping and therefore no history of maintenance work that was done

- No information about which assets incurred the most maintenance costs

- Uncontrolled and escalating backlog

- Duplicate tasks or work orders

- Uncertainty about the status of preventive and statutory maintenance

Work being prioritised based on gut feel - No planning of work, resulting in delays while resources are mobilised and information prepared

- No scheduling of work, resulting in conflicts with Operations

- Overloaded or underutilised resources

- Inability to forecast labour, materials and spare parts requirements.

The advantages of work planning and control

With WPC in place, unpleasant surprises are eliminated and the scene is set for a stable and predictable environment that works according to predefined rules.

Basic WPC in place gives you:

- Peace of mind that preventive and statutory tasks are being done.

- Accurate maintenance costing, including labour, contractors and spare parts.

- A realistic account of backlog and an effective system to reduce the initial backlog, moving from reactive maintenance to proactive maintenance.

- Easy identification and safe removal of duplicate tasks and work orders.

- A simplified and semi-automated planning and scheduling cycle.

Advanced WPC in place gives you:

- Better utilisation of the maintenance staff’s time.

- Improved coordination between Operations, Maintenance and stores.

- Accurate budgeting based on forecasted tactical maintenance, labour and spare parts.

- Availability of spare parts and other resources when needed.

- Optimal utilisation of equipment stoppages for opportunistic maintenance.

- Elimination of wasteful waiting time.

- Proper prioritisation of maintenance work according to predefined rules.

Pragma’s approach to work planning and control

To get a basic WPC process in place, we do a thorough analysis of your current process. As this will form the basis of an advanced WPC process, we focus on your basic work order requirements and workflow.

- Reviewing the work order layout, work order types and work order statuses

- Developing and implementing standard work management processes

- Setting up all existing preventive maintenance tasks in the CMMS/EAMS

- Running the weekly list of preventive maintenance to be done

- Creating work orders for all requested work

- Monitoring and controlling the execution of all work orders through backlog management and scheduled compliance reports

- Accurate capturing of completed work orders into the CMMS/EAMS

- Provision of a variety of reports on asset costs and performance, based on a growing database

- Improved equipment uptime results from preventive maintenance.

Advanced WPC with full planning and scheduling

- Work is prioritised according to importance, best practice and an industry standard algorithm

- Formal planning of all non-urgent work to ensure optimal utilisation of the maintenance staff and the availability of material, tools and permits as required

- Scheduling of maintenance work in conjunction with Operations for a rolling three-week window

- Daily allocation of work to the most appropriate resources

- Managing urgent “break-in work” on a daily basis

- Three-day training workshop on the details of advanced planning and scheduling.

Maintenance management made easy with On Key

A best of breed maintenance management system is critical for the success of your WPC process.

Although we work with a multitude of reputable maintenance management systems, we find that On Key’s work management module perfectly support the smooth running of WPC processes. Here is why:

- Variety of work order types

- Work order progress can be monitored via user-defined work order statuses

- Resources, maintenance cost and labour can be attached to work orders

- Work can be allocated to trades, workshops or contractors

- Work can be scheduled to weeks or events

- View work orders that have been created for a specific asset over a predefined period

- Tactical work can be triggered based on calendar time, meter readings or condition monitoring

- Failure codes are used to support root cause analysis and focused improvement

- Response times and work completion can be managed against SLAs, with associated notifications

- The Work Manager app allows tradespeople to receive work orders on their personal tablets or laptops and capture work order feedback directly

- A variety of SSRS reports are available to manage the work

- On Key Insights allows for in-depth analysis and optimisation of the work management