Elevating manufacturing operations with effective maintenance management

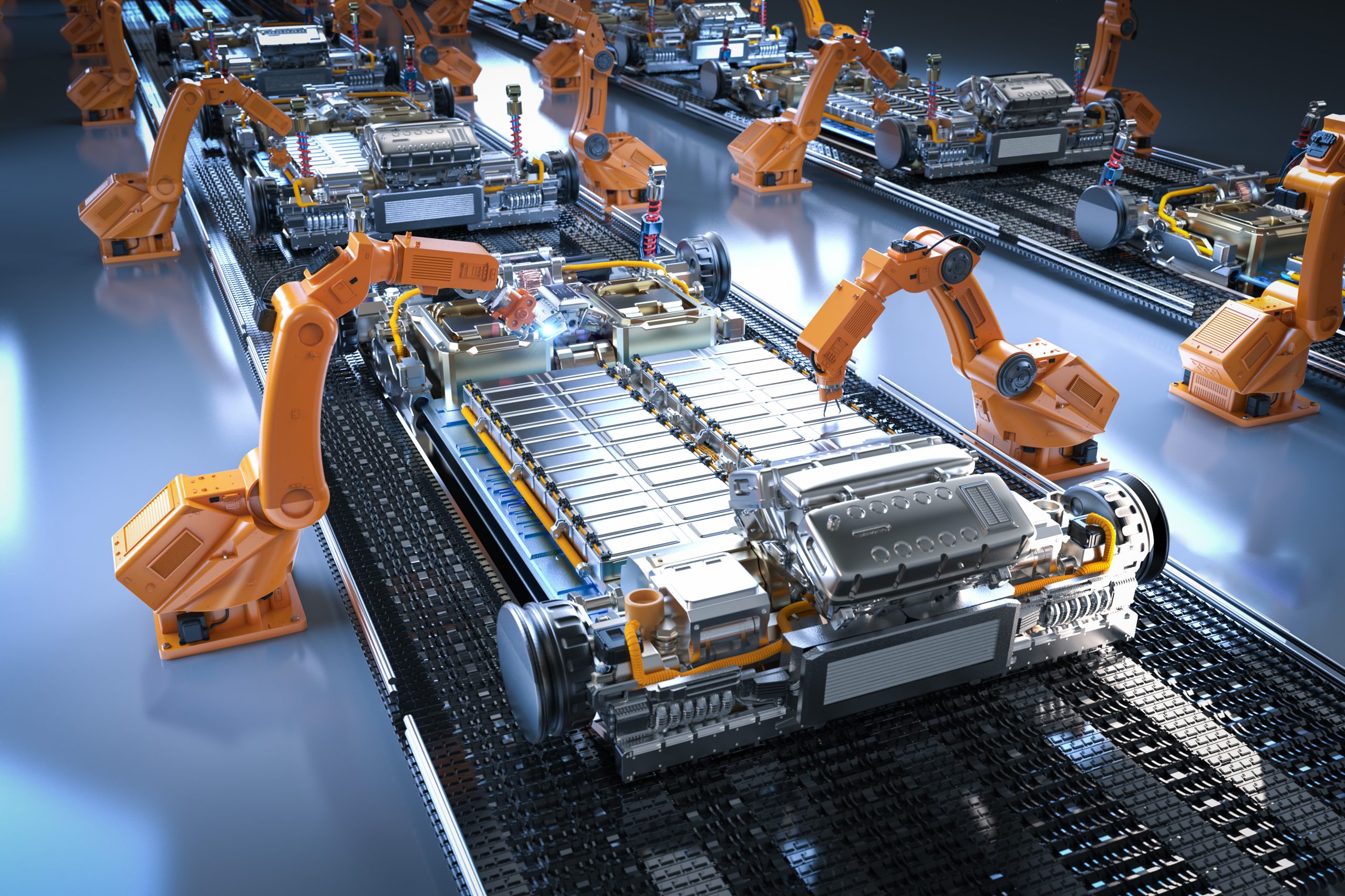

The manufacturing industry is undergoing rapid change, necessitating companies to embrace advanced technologies for success. Agility, flexibility, and sustainability are crucial for adapting to market shifts and implementing scalable production processes. However, numerous manufacturing plants still depend on a combination of outdated and smart equipment, which poses distinctive challenges.

Regardless of their circumstances, manufacturing plants in various sectors require smooth operations to achieve high productivity and profitability. A well-designed maintenance management programme is indispensable in this regard.

Pragma acknowledges the importance of tailoring maintenance solutions to meet the specific needs of each plant and takes pride in providing effective programmes to manufacturing clients.

Asset performance management and maintenance

Maintenance innovation is crucial in the fast-paced manufacturing industry. Collaboration between humans, processes, and technology ensures reliable equipment for the changing demands of the plant. Advanced technologies and real-time monitoring sensors revolutionise maintenance practices. Swift issue identification and resolution prevent costly delays and downtime. Predictive maintenance proactively determines maintenance requirements using machine learning algorithms and sensor data analysis. Skilled maintenance technicians are vital for effective implementation. They diagnose issues, perform routine tasks, and make repairs. Digitalised maintenance processes streamline planning and execution, reducing redundancies and paperwork, enhancing efficiency, and minimising downtime.

Streamlining after-sales technical services for OEMs

After-sales technical services are essential to keep your client base happy and loyal. We help OEMs get full visibility across their complete installed base while managing service contracts and all service events delivered by field engineers and contractors with our asset management service. The On Key product suite plays a significant role in digitalising work processes to speed up turnaround time, eliminate human error and complete sign-off and contractor invoicing.

Process driven asset management for fast moving plants

In the fast-paced world of manufacturing, every second counts. A digitalised workflow is an essential tool to achieve production targets while ensuring compliance and quality. Our mobile applications enable artisans to log work requests and initiate the work management process instantly without wasting valuable time. By scanning and identifying the exact equipment, our system ensures that the highest priority is given to critical assets, such as conveyors on an assembly line, that require immediate attention.

Our digitalised process ensures consistency across rotating teams, allowing uninterrupted maintenance across shifts. Progress is tracked and managed, triggering subsequent steps. This guarantees proper record-keeping in the asset management system, offering valuable insights into breakdowns, maintenance needs, and associated costs.

Our solutions for the automotive industry

Your baseline | an asset management maturity assessment

To enhance plant reliability and maintenance, it is vital to have a clear understanding of its current condition. Regardless of the size or complexity of your plant, a comprehensive asset management improvement assessment can uncover the root causes of issues such as downtime, recurring breakdowns, spares shortage, underperforming units, waste, compliance problems, and more.

With Pragma’s asset management maturity assessment, you can gain deep insights into your plant’s performance, enabling you to prioritise and allocate budgets effectively. With this information, you can develop a winning strategy, policy, and asset management framework to elevate your plant.

Training or co-sourcing to fill the skills gaps and expertise in your team

Cutting-edge technologies are transforming the manufacturing workforce by automating routine tasks. However, skilled workers are still essential for operating, maintaining, and troubleshooting these technologies. This may involve training or upskilling existing workers for new roles.

Skills shortages pose a common challenge for companies, but Pragma addresses this issue by providing services that bridge critical skills gaps.

Our scalable asset care service assists clients of various sizes and needs with maintenance management requirements. Our engineers can work alongside a client’s team or take full responsibility for their maintenance management function. We can also bring in specific skill sets as needed.

Reliability engineering to manage your assets optimally

Formal maintenance plans are insufficient to ensure optimal equipment functioning and plant reliability. That’s where reliability engineering comes into play – it is the key to identifying and eliminating defects in critical assets to maximise their performance throughout their entire lifespan. For instance, by resolving recurring blockages in a spray gun at an automotive plant or addressing the root cause of faulty calibration in a pharmaceutical filling station, reliability engineering can minimise rework, waste, costs, and potential damage to reputation. At the core of reliability engineering lies the development of maintenance plans tailored to the specific needs of each asset. This entails selecting the most suitable maintenance tactics, considering the asset’s criticality, age, usage, and operating conditions.

Work management processes that deliver measurable results

Effective work management is vital for successful maintenance programs in manufacturing plants. It encompasses various elements such as asset creation, acquisition, efficient operation, standard maintenance, risk assessment, and outage management.

Although the concept may seem simple, work management is a complex process that requires expertise to execute effectively. Pragma understands this well and offers comprehensive best practices to streamline maintenance processes while ensuring safety and compliance.

Our best practices are beneficial for standardising work practices, rates, and completion times across different plants and coordinating work between internal technicians and contractors. By implementing our work management processes, you can maximise asset uptime, minimise downtime, and achieve optimal plant performance.

If your team needs support in managing your asset management programme, we can help.