For as long as asset owners have built and operated complex assets, structuring an asset management team that has the right skills and capacity has been difficult for many engineering executives. Providing the appropriate level of maintenance management and reliability engineering skills in a changing and resource-constrained environment remains challenging – but asking a few questions to better define what your business needs may increase your success levels. In this article, we will try to cover the most important questions we encounter when helping clients design the capability set and structure that will help them balance performance, cost and risk across their asset base.

1. How complex and diverse are the assets you are responsible for?

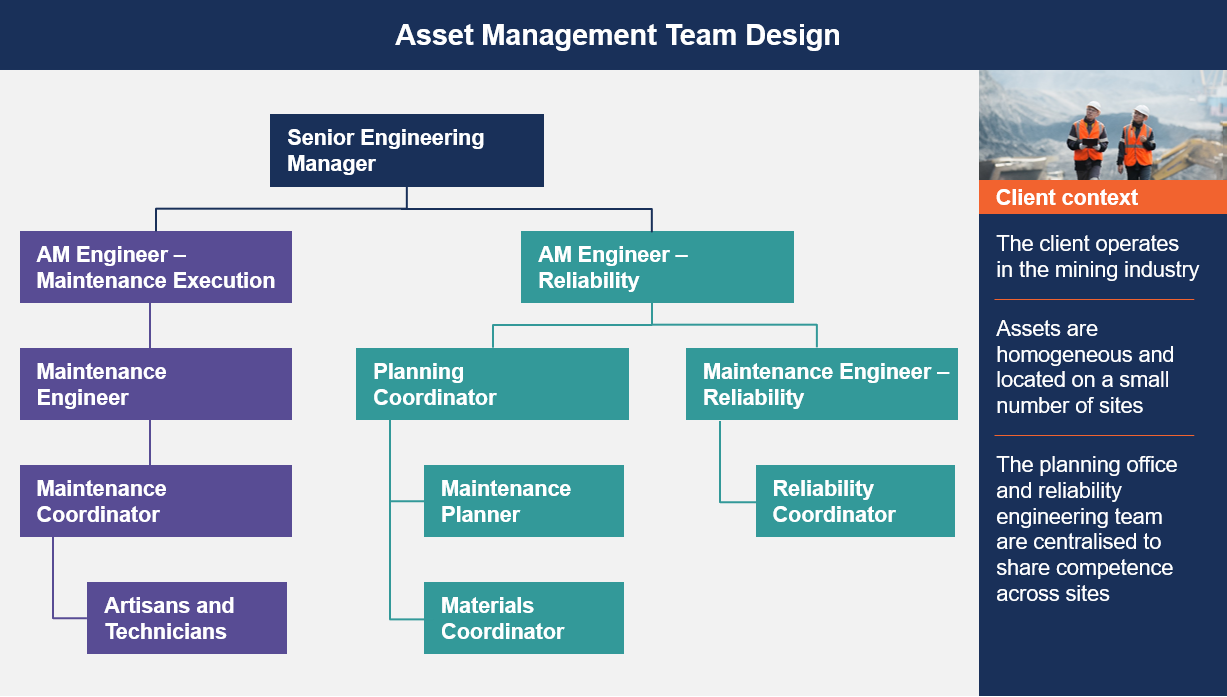

Designing an asset management team often requires balancing the efficiency (and therefore cost) of maintenance management processes with having access to very specialised reliability engineering or design skills to solve complex reliability or performance problems. Maintaining a very complex asset base, or one that contains many different types of assets, requires many unique analyses and design cycles to rectify reliability or performance problems. If the asset base is more homogeneous, failure and performance patterns are easier to identify, and the focus should be on the controlling, work planning and execution process. Matching the skill allocation in your asset management team to the demands of the asset base will increase team performance, job satisfaction and overall costs.

2. How widely are the assets distributed?

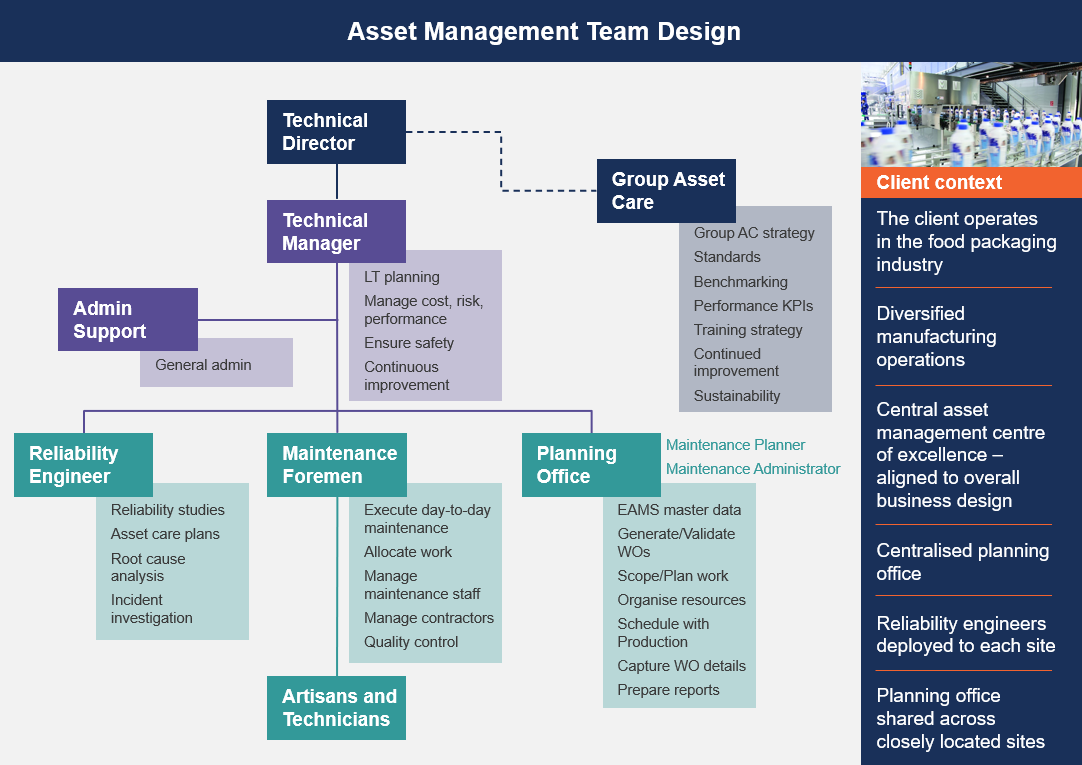

When selecting which resources need to be on site and which can be shared, the geographical distribution of assets and sites is an important consideration. While frontline maintenance and operations staff need to be close to the assets, placing maintenance or reliability engineers on every site is not always ideal. The more specialised planning and engineering skills are most often placed in shared centres of excellence from where they can be deployed to sites based on specific needs, such as statutory inspections or managing shutdowns. We can lower risk exposure by reducing travelling to sites. We can optimise where the availability of certain skills in the assets’ geo-locations are, and determine which resources are shared in regions and which will be placed on site permanently.

3. What role do OEMs play in your maintenance strategy?

Many Original Equipment Manufacturers (OEMs) are offering maintenance service contracts and even performance guarantees to asset owners. If asset owners make use of these features, the responsibility for managing equipment availability, spares provision and planning for labour availability is transferred to the OEM service team. In an environment where a significant number of OEM service contracts are in place, the ability to manage the contracts and service provider relationships will be an important requirement for the asset owner to manage their performance.

4. Are you an OEM driving a service strategy?

OEMs targeting a revenue stream from service or performance contracts still require all the planning, work management and reliability engineering skills, but what else? Transferring risk from asset owner to service provider requires new operational capabilities in areas such as predictive analytics, asset health monitoring, logistics planning and contractor management. Several new commercial models are emerging in this space, focused on customer lock-in and partnering with insurance players to diversify the risk profiles of new contracts. The choice of business model will determine which of these skills need to be included in your maintenance capability or structure.

5. What role will your corporate operating model play?

Most corporations have a chosen design philosophy for their operating model, defining the level of de-centralisation in decision making and variability of business policies and processes. This philosophy will also influence your organisation’s guidelines for infrastructure selection, business process design, organisation structure design and systems configuration. It may be necessary to align your asset management team design to these principles for the design to be effectively integrated into the rest of the business. These decisions will determine how shared centres of excellence, site-level organograms and implied delegations of authority are used in your design.

6. Are you investing in technology to allow virtualisation of skills?

The adoption of connected worker (CW) and augmented reality (AR) solutions is on the upswing as corporates look to improve maintenance worker productivity, safety and satisfaction through innovative technologies. Expanding the use of CW and AR technology can impact maintenance activities across the whole asset lifecycle: by providing remote assistance during plant commissioning, remote expertise and oversight to on-site workers while performing inspections, and just-in-time training of junior technicians. Investments in these technologies could significantly impact which skills are placed where in your organisation.

Choices and their consequences

In reality, there are no ‘right’ answers – only choices and consequences that will impact your ability to design an effective, well-capacitated team that is aligned to your overall organisation architecture. We close out with examples that show how two of our clients have designed very different asset management teams as they navigated this journey.