Preparing a new or refurbished plant ready for commissioning is no small feat. The anticipated honeymoon phase of a newly commissioned plant with equipment operating optimally, production being at the required rate, and no unplanned stoppages can be short-lived if the vital element of asset care is not in place. To avoid performance and operational disappointment, or even worse, shortening your asset’s life cycle, it is critical that your plant and equipment are maintenance ready by the time you flick that switch from project to operations.

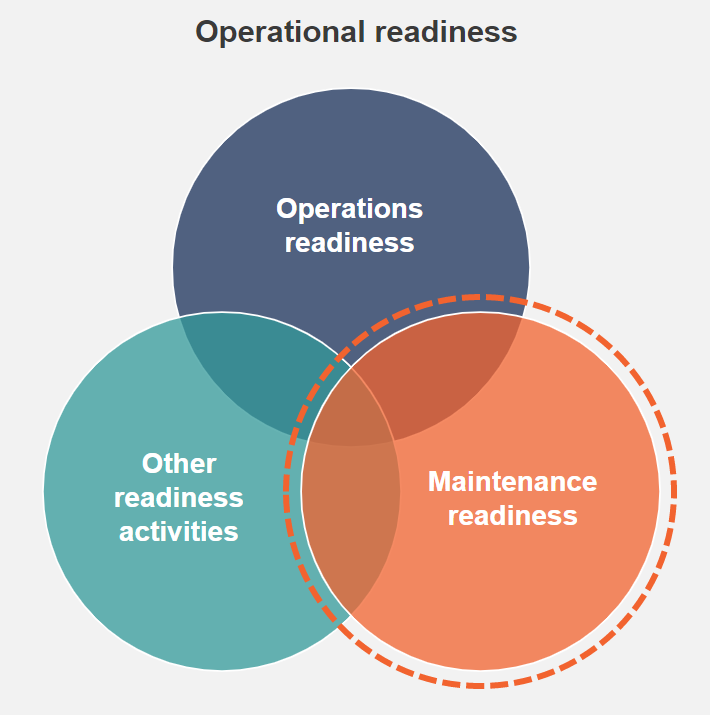

When we consider maintenance readiness, we focus on the maintenance and reliability-related activities within the operational readiness landscape. Maintenance readiness includes the processes and activities required to ensure that enterprise assets are designed fit for purpose and are ready to maintain at project handover.

The maintenance readiness process can be applied to greenfield establishments (eg brand new plants, mines, buildings), brownfield extensions (eg extending current plants), procurement of a new major piece of equipment, or the extensive rehabilitation of a major process or facility.

The successful close-out of these projects will depend on many activities across several inter-related themes; one of the most important of which is that of reliability and maintainability.

On a granular level, asset reliability is the ability of an asset to perform its intended function for a specified interval under stated conditions. In this article, we take a look at the role of reliability block diagram software, and reliability specifications in the maintenance readiness landscape, and their influence on the final project design and improved ROI.

Influencing the design

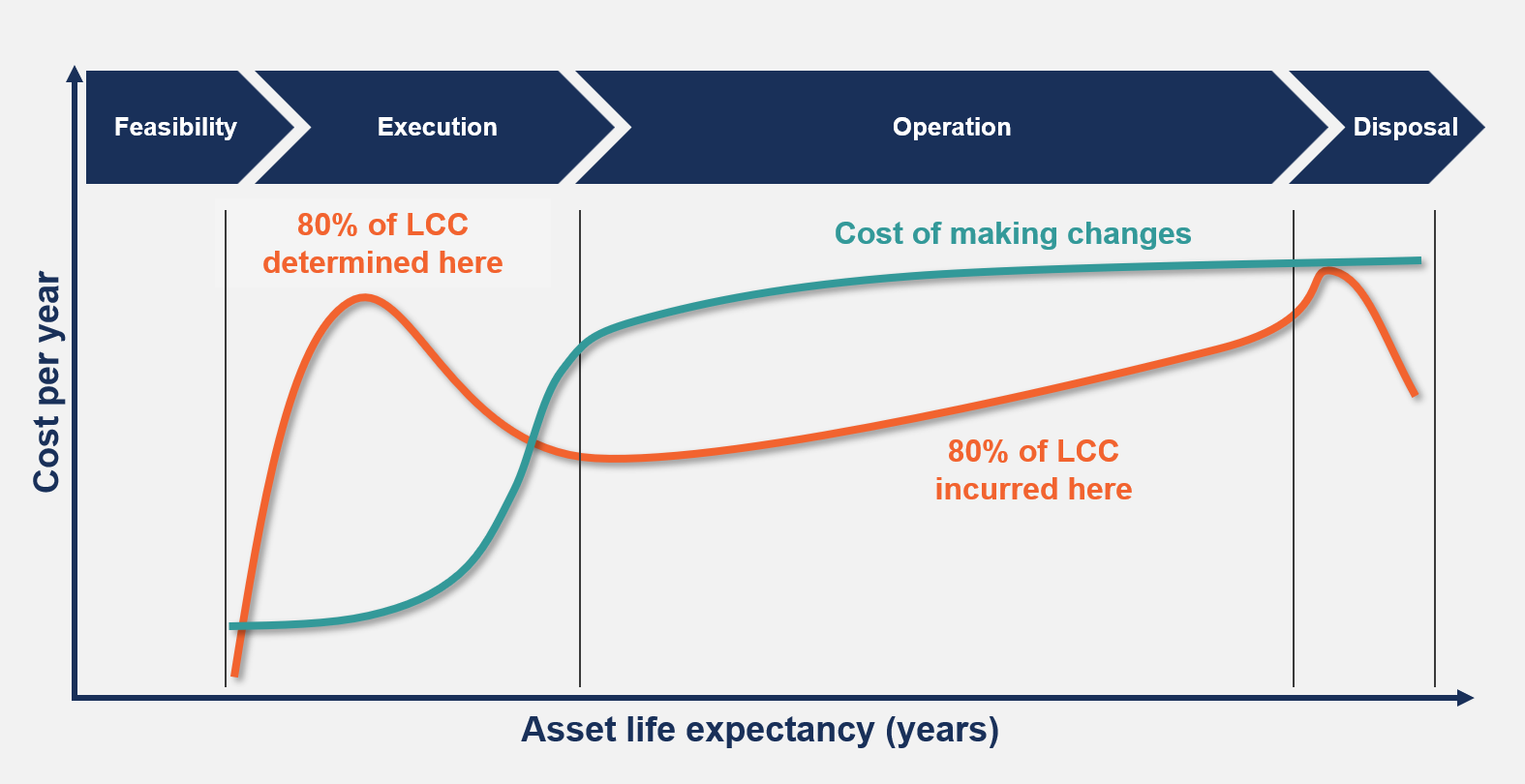

Reliability should be designed into the project, as it is during the design stages where the cost of making changes is relatively low. It is during the design stage that 80% of the asset’s operational life cycle cost (LCC) is determined – leaving reliability engineers limited opportunity to improve LCC once it is operational.

Our reliability engineers use best-of-breed reliability block diagram software, reliability specifications, and and draw on their vast experience to determine optimal reliability.

Reliability block diagrams

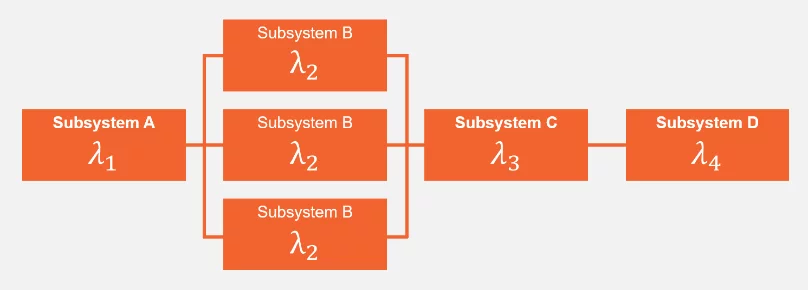

Once provided with the detailed design/s our engineers begin the process of feasibility and maintainability analysis. We use best-of-breed reliability block diagram (RBD) software to analyse the system using an efficient Monte Carlo simulation process. This provides availability, capacity and reliability parameters, life cycle costs, importance rankings, and so forth. Thus, the client is provided with a simulation/s of the reliability of the plant, based on the designs provided.

Reliability block modelling and simulations of assets provide the capability to model the connectivity of production assets. Thus assessing their reliability and availability as a collective system, a production unit, or complete facility. In addition, given the historical values that have been determined through reliability distribution analysis, analytical simulations can be performed to understand the future reliability behaviour of assets. What-if simulations can also be performed to compare changes in asset configurations, changes in the asset tactics, or changes in reliability.

Reliability and maintainability analysis

Depending on the type of investment project, and providing our client with the RBD diagrams we will also conduct reliability and maintainability analysis. RAM (and its permutations) can be defined as a number of activities conducted to understand and improve the reliability of systems and assets.

RAM | A review of the Reliability, Availability and Maintainability of the system and assets of the new investment. Note that Availability and Accessibility are both interpretations of the “A” in RAM. Accessibility is generally more useful once the asset selection stage is complete, but it can also be incorporated into the Maintainability review activity. RAM’s sessions are the ideal opportunity to finalise the specifications for procurement work packages and start documenting acceptances criteria.

RAMBO | Buildability and Operability are added to RAM. Buildability is a specific review, mainly aimed at streamlining the construction process. During refurbishment or replacement, assets may need to be dismantled – accordingly, it is often appropriate to combine Buildability and Maintainability in a common review session. Operability considers the practical aspects of operating the plan after commissioning. Experienced process and production resources are required in the review session to add value.

RAMBOS | Safety is added as a specific review topic, often with a different review team participating. Safety and Security are both interpretations of the “S” of RAMBOS. In precious metal and gem applications, a security review is essential, as part of the review process. It makes sense to perform the safety review as part of the maintainability and operability reviews – it is during these discussions of how to maintain and operate that safety should also be considered.

Readiness for opportunity makes for success. Opportunity often comes by accident; readiness never does. – Sam Rayburn

Influencing the final design

Based on the results from the model or simulation, a thorough report is generated with actions for improving or optimising the performance of the asset(s) for the design team’s consideration.

A common saying in the industry is that “reliable operations are safe operations, and safe operations are reliable operations – and safe and reliable operations are usually profitable operations”.

The proper management and maintenance of equipment on a newly commissioned plant can immediately fall behind if not properly planned. Gain a deeper insight into the cost and value of your assets by ensuring that a Maintenance Readiness project forms part of your Operational Readiness project.

Visit our Maintenance Readiness webpage for more information about our customised maintenance readiness approach.